Eliminate the hard work of managing the supply chain with IoT

Living in the 21st century should be considered a blessing. We are able to get many difficult tasks done without putting in too much hard work. As we know, traditionally, supply chains have faced many challenges relating to cost and complexity. The risk we are taking with human efforts to complete work will almost certainly result in some errors. This not only causes pain in service providers but the consumers, as they are the ones who will be deciding how they received your service. That is why it was a much-needed requirement of an hour with the Internet of Things (IoT).

The Internet of Things (IoT) has revolutionized the way we do business, and nowhere is this more evident than in the field of supply chain management and logistics. With the advent of Industrial IoT (IIoT), companies can now automate many tedious and time-consuming tasks that were once the domain of human workers.

The worldwide logistics business was worth almost $8.6 trillion US dollars in 2020. In that year, North America was the second largest region, accounting for nearly two trillion US dollars. The logistics market in the Asia Pacific region is the largest in the world, with a value of over 3.9 trillion US dollars. The Asia-Pacific region also boasts the most post offices in the world. PSA International’s revenue varied by about four billion Singapore dollars between the 2009 and 2020 fiscal years, producing slightly more than 4.1 billion Singapore dollars in the fiscal year 2020.

With the above data, we can conclude that the logistics chain is huge and the market will require the presence of IoT on a large scale. With the increasing size of the current business, it can only be filled by automation and connectivity. To address these issues, supply networks must become smarter. At IOSCAPE, we use the Internet of Things (IoT) in supply chain management (SCM) by building a smart and secure SCM system that combines data, information, goods, physical objects, and all supply chain operations.

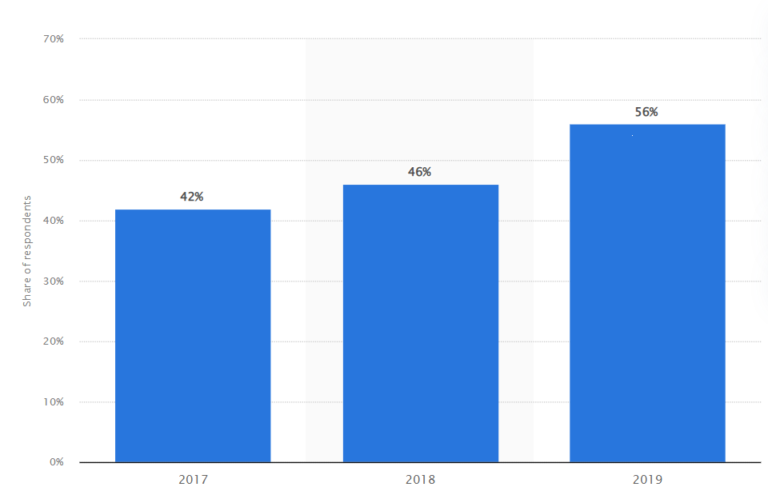

As amazing as the IoT is, it has been recognized by market leaders as well. According to a 2019 poll, 56 percent of supply chain leaders want to invest in sensors and the Internet of Things (IoT) in 2019. So many leaders in this industry have realized that IoT will improve supply chain management. This opportunity should not be missed. IOSCAPE is helping to start building a roadmap for supply chain transformation to digitalization.

The cost of human error is high, and it also results in a loss of business. This has been happening when we have a more centralized and hierarchical approach, in which a single organization or entity is responsible for managing the entire supply chain. Even with IoT present, half of supply chain management is still missing out. Organizations may enhance operational efficiencies and save time and money by implementing digital transformation.

In the past, supply chain management, and logistics were heavily dependent on manual processes. This included tracking and monitoring the movement of goods, updating inventory levels, and forecasting demand. However, with the IIoT, companies can now automate many of these tasks, freeing up human workers to focus on more critical tasks.

Eliminate the hard work of data processing.

The ability to collect, store, and analyze data is essential for making informed decisions in a supply chain management ecosystem. This data can include information on inventory levels, delivery times, and customer demand. IoT can improve scalability by providing real-time data on inventory levels and demand. This can help companies better plan for the future and quickly respond to changes in demand.

Get the visibility of the work

In traditional supply chains, it can be difficult to track and monitor the movement of goods. This lack of visibility can lead to delays and errors, which can ultimately impact customer satisfaction. IoT-enabled devices such as sensors, RFID tags, and GPS tracking can be used to track and monitor the movement of goods from the point of origin to the final destination. This allows for real-time visibility and improved efficiency in the supply chain, which can help companies make more informed decisions. For example, if a shipment is delayed, companies can quickly reroute it to avoid further delays.

You definitely want more flexibility

Traditional supply chains are often rigid and inflexible, making it difficult to adapt to changing market conditions. Because of the following reasons:

● Centralized decision-making: Traditional SCM often relies on a centralized decision-making model, in which a single entity is responsible for managing the entire supply chain. This can lead to delays and inefficiencies as decisions need to be passed through multiple levels of the organization before being implemented.

● Lack of real-time data: Traditional SCM often lacks the ability to provide real-time data on inventory levels, delivery times, and other important metrics. This can make it difficult to quickly respond to changes in demand and market conditions.

● Limited collaboration: Traditional SCM often involves less collaboration among partners and intermediaries in the supply chain, which can result in delays, errors, and inefficiencies.

● Lack of automation: Traditional SCM often relies on manual processes and lacks automation, which can be time-consuming and prone to errors.

● Limited scalability: Traditional SCM is often designed to handle a specific volume of goods and can be difficult to scale up to meet increased demand. Traditional supply chains often rely on manual processes, which can be time-consuming and prone to errors. This can lead to inefficiencies in the supply chain, which can increase costs and reduce customer satisfaction.

● Limited transparency: Traditional SCM often lacks transparency, which makes it difficult to identify bottlenecks and other issues in the supply chain.

The Internet of Things (IoT) plays a significant role in Industry 4.0, particularly in supply chain management and logistics. IoT-enabled devices such as sensors, RFID tags, and GPS tracking can be used to track and monitor the movement of goods, from the point of origin to the final destination. This allows for real-time visibility and improved efficiency in the supply chain.

Optimize your logistics

By providing real-time data on traffic, weather, and other factors that can impact delivery times. This can help companies make more informed decisions and improve delivery times, ultimately leading to increased customer satisfaction. The Internet of Things (IoT) has the potential to overcome many of the problems faced by traditional supply chains and logistics. Some of the ways IoT addresses these problems include:

● Automation: IoT can automate many of the manual tasks associated with supply chain management and logistics, reducing labour costs and minimizing the need for human intervention. This can reduce the risk of errors and improve the overall efficiency of the supply chain.

● Fragmentation: IoT can help to improve coordination among partners and intermediaries in the supply chain by providing real-time data and enabling better communication.

● Flexibility: The IoT can provide real-time data on market conditions, which can help companies quickly adapt to changing conditions.

● Real-time data: IoT can provide real-time data on inventory levels, delivery times, and other important metrics, which can help companies to make informed decisions and optimize logistics.

● Cost-effectiveness: IoT can help reduce costs by automating many of the manual tasks associated with supply chain management and logistics, and by improving efficiency.

Give the best service to your customers.

Traditional SCM often lacks the ability to provide real-time information to customers, which can make it difficult to provide good customer service and meet customer needs. IoT can provide real-time information to customers, which can help to improve customer service and meet customer needs. Providing information to customers can help to improve customer service, build trust, and increase customer satisfaction. It can also enable customers to make more informed purchasing decisions and to be more loyal to the company.

Customers may look for several types of information in a supply chain management (SCM) system, including:

● Product availability

● Delivery times

● Order Status

● Return and refund policies

● Product information

● Pricing

● Customer service

● Supply Chain sustainability

Get that huge potential

It’s worth mentioning that, while IoT has the potential to overcome many of the problems faced by traditional supply chains and logistics, it’s not a silver bullet. Implementing IoT solutions can be a complex process. At IOSCAPE, we will help you understand the complex process and implement it easily.

IIoT is transforming the way we do supply chain management and logistics. With its ability to automate many of the tedious and time-consuming tasks associated with these fields, the IIoT is helping companies improve efficiency, reduce costs, and increase customer satisfaction. As such, it’s an essential technology for any company that wants to stay competitive in today’s fast-paced business environment.

You’re looking for ways to increase efficiency and save money in your supply chain.

We have the perfect solution – IOSCAPE. Our platform connects all aspects of your supply chain, making it more intelligent and cost-effective. And we do it all without breaking the bank.

Imagine a future where you can monitor every step of your supply chain in real-time, from production to delivery. With IOSCAPE, that future is now. Contact us today to learn more about how we can help you streamline your business and save money.Request a demo today or visit our website to learn more!